At Iberoquinoa we rely on

the most cutting-edge facilities in which quinoa is exclusively produced with seeds from our farms,

obtaining a final product ready for consumption.

Our process is completely automated and is integrated with the most advanced machinery in the sector, this allows us to obtain maximum efficiency. Furthermore it is a

fully isolated work line,

preventing any type of contamination, offering a safe product for the consumer.

Our process is completely automated and is integrated with the most advanced machinery in the sector, this allows us to obtain maximum efficiency. Furthermore it is a

fully isolated work line,

preventing any type of contamination, offering a completely safe product for the consumer.

Harvest and transport

Automated harvest of quinoa once dried – the use of machinery and vehicles which stick to the corresponding cleaning and security protocol to ensure that there is no risk of cross contamination and guaranteeing a completely gluten free product.

Storage

Silos with a capacity of storing more than 8,000,000 kg

which exclusively store quinoa.

Processing

Capacity for more than 3,000 kg/ hour of raw product. Computerised work line which ensures absolute control of every phase in the process:

Elimination

of impurities

leaves, sticks, gravel,

dust, etc.

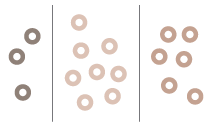

Classification:

by size and colour

to obtain a completely

uniform grain.

Polishing

of the grain:

to eliminate saponin and

to give a smooth appearance.

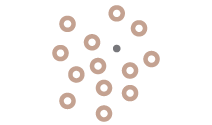

Detection

of metals:

For a product

safe for consumption.

Packaging

We adapt to our client’s needs, being able to package our quinoa

in bags of 10 to 25 kg, up to big bags of 1000 kg.